TricorBraun Flex joins the How2Recycle Program with our mono-material structure

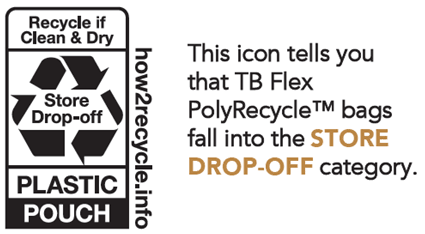

TricorBraun Flex has developed PolyRecycle™, a How2Recycle pre-approved, flexible polyethylene (PE) film packaging material. PolyRecycle™––which works well with dry, free-flowing products with low barrier requirements–– is available now and pre-qualified for Store Drop-off by consumers in the US, and curbside in Canada. Brands must be a member of How2Recycle and submit a request in order to utilize this labeling system. Store drop-off locations can be found at how2recycle.info/sdo.

TricorBraun Flex has developed PolyRecycle™, a How2Recycle pre-approved, flexible polyethylene (PE) film packaging material. PolyRecycle™––which works well with dry, free-flowing products with low barrier requirements–– is available now and pre-qualified for Store Drop-off by consumers in the US, and curbside in Canada. Brands must be a member of How2Recycle and submit a request in order to utilize this labeling system. Store drop-off locations can be found at how2recycle.info/sdo.

- The How2Recycle label includes clear and concise recycling instructions

- Store drop-off locations can be found at how2recycle.info/sdo

- Pre-approved PolyRecycle™ structure simplifies the How2Recycle process

For more information about How2Recycle, visit the website. To inquire about TricorBraun Flex’s pre-qualified materials, please contact 800.562.2247.

For more information about How2Recycle, visit the website. To inquire about TricorBraun Flex’s pre-qualified materials, please contact 800.562.2247.

TricorBraun Flex Digital

Are you a startup company looking for outstanding custom printed package? Do you have seasonal or occasional products which only require few hundreds of printed package? Are you thinking of personalizing your products with distinct “one of a kind” package? With latest digital printing technology, TricorBraun Flex has the solutions! TricorBraun Flex is proud to introduce digital printing to our customers which provides solutions for small and urgent runs.

Are you a startup company looking for outstanding custom printed package? Do you have seasonal or occasional products which only require few hundreds of printed package? Are you thinking of personalizing your products with distinct “one of a kind” package? With latest digital printing technology, TricorBraun Flex has the solutions! TricorBraun Flex is proud to introduce digital printing to our customers which provides solutions for small and urgent runs.

Here are benefits for digital printing.

No more set up costs. Unlike traditional conventional printing technology such as roto-gravure printing or flexo printing, digital printing does not require cylinder or plate. That means, no more costly set up costs.

Speed to market. Because printing is done digitally, we can go straight to production from digital files. This eliminates lengthy cylinder engraving and proofing process. Digital printing shortens the timeframe significantly for launching new products and re-branding. Digitally printed packages can be completed and delivered to you within 10 ~ 15 working days after artwork approval!

No more commitment to long runs. Since there is no production waste while starting up digital printing press, we can technically custom print only one bag. At the same time, raw material can be fully utilized. This technology breaks down the MOQ (minimum order quantity) barrier from conventional printing. Everyone can have custom printed packages.

Eliminate registration issues. Digital printing does not have trap line or dot gain. All color inks are transferred to the substrate all at once instead of one color after another color in traditional gravure or flexo printing procedure. That means, we can 100% eliminate the possibility of having color registration or trapping issues.

Endless possibilities. Differentiate your products from others by having distinct packages. Every single piece of print can be personalized and customized. Be creative on packaging and let us assist you selling more of your products.

Biotrē™

Our Biotrē™ product line started in 2011 as our starting point down the path of true sustainability, and our journey is far from over. At TricorBraun Flex we continue to expand our Biotrē™ films and with each film we develop we get closer to our simple goal; providing the industry with packaging that protects both product and the planet.

Learn more

Child Resistant Bag

Introducing the world’s first lab certified child-resistant bag. With its proprietary pull to open locking zipper, thick food-grade plastic, and extra durable construction, these opaque bags provide peace of mind to parents, and law enforcement officials to ensure that medicine and dangerous items won’t end up in the wrong hands.

With a proprietary pull to open locking zipper, our pouches provide a child-resistant solution to safeguard dangerous and toxic items that don’t fit into a pill vial: cosmetics, household cleaners, detergents, batteries, toys … the uses are endless!

Our child resistant pouches are classified in accordance with ASTM D3475 and are lab tested and certified using CPSC standards and protocol to conform to the requirements of a Poison Prevention Package (16 CFR 1700).

Learn more

Microwavable Packages

Let microwavable self-venting feature increases the value of your package and product. Microwavable self-venting feature enhances product’s ease of use and makes food preparation convenient for consumers. TricorBraun Flex is proud to implement WaveQuick™ Self-Venting technology for microwave applications.

With WaveQuick™ technology, micro-perforated vent holes are applied to laminated structure. We perforate film in necessary venting pattern and depth depends on products and desired microwaving time. The technology allows steam to escape as the products are being microwaved. No piercing is required. At the same time, the package is completely airtight, no excessive loss of moisture, and maximizes mineral and nutrient retention. Products can be cooked quickly and evenly while leaving the moist and tender.

TricorBraun Flex microwavable self-venting technology can be applied to both rollstock film and pre-made pouches. It is perfect for frozen produce, seafood, meats, ready-to-eat meals…

Pocket Zipper

Pocket Zipper, also known as Front Zipper, is one of TricorBraun Flex’s latest innovated re-closing systems. The re-closing zip-lock is applied to the front side of the package only. Since the re-closing system is on the front of the bag, it creates convenience and trouble free filling experience. Fillers do not require pre-opening the zip-lock before filling the products. For machine fill production line, pouches with Pocket Zipper also reduce filling error by providing 100% open pouch for every single fill. Block Bottom Bag with Pocket Zipper also creates a wide opening for filling comparing to other re-closing systems. For consumers, Pocket Zipper allows easy dispensing especially for powder and granular products. Pocket Zipper can be applied to Stand-up pouch and Block Bottom Bag.

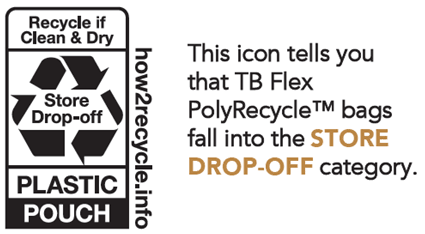

TricorBraun Flex has developed PolyRecycle™, a How2Recycle pre-approved, flexible polyethylene (PE) film packaging material. PolyRecycle™––which works well with dry, free-flowing products with low barrier requirements–– is available now and pre-qualified for Store Drop-off by consumers in the US, and curbside in Canada. Brands must be a member of How2Recycle and submit a request in order to utilize this labeling system. Store drop-off locations can be found at how2recycle.info/sdo.

TricorBraun Flex has developed PolyRecycle™, a How2Recycle pre-approved, flexible polyethylene (PE) film packaging material. PolyRecycle™––which works well with dry, free-flowing products with low barrier requirements–– is available now and pre-qualified for Store Drop-off by consumers in the US, and curbside in Canada. Brands must be a member of How2Recycle and submit a request in order to utilize this labeling system. Store drop-off locations can be found at how2recycle.info/sdo.

For more information about How2Recycle, visit the website. To inquire about TricorBraun Flex’s pre-qualified materials, please contact 800.562.2247.

For more information about How2Recycle, visit the website. To inquire about TricorBraun Flex’s pre-qualified materials, please contact 800.562.2247.

Are you a startup company looking for outstanding custom printed package? Do you have seasonal or occasional products which only require few hundreds of printed package? Are you thinking of personalizing your products with distinct “one of a kind” package? With latest digital printing technology, TricorBraun Flex has the solutions! TricorBraun Flex is proud to introduce digital printing to our customers which provides solutions for small and urgent runs.

Are you a startup company looking for outstanding custom printed package? Do you have seasonal or occasional products which only require few hundreds of printed package? Are you thinking of personalizing your products with distinct “one of a kind” package? With latest digital printing technology, TricorBraun Flex has the solutions! TricorBraun Flex is proud to introduce digital printing to our customers which provides solutions for small and urgent runs.